- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Water is a vital resource, but when not properly managed, it can cause significant damage. Leaks, flooding, and water accumulation pose risks in homes, industries, and the environment. This is where water detection sensors come in.

In this article, we will explore the various types of water detection sensors, including Multiparameter Sensors, which measure multiple water quality parameters at once. You'll learn how these sensors work and how to choose the right one for your needs.

Water sensors can be classified based on the technology used for detection and the application requirements. Below are some of the most commonly used types of water detection sensors:

Capacitive water sensors detect water by measuring changes in capacitance caused by the presence of water. These sensors consist of two conductive electrodes separated by a non-conductive material. When water comes into contact with the electrodes, it alters the capacitance, triggering an alert.

● How they work: Capacitive sensors rely on the electric field surrounding the sensor. When water changes the dielectric constant of the material between the electrodes, it leads to a measurable change in capacitance.

● Applications: These sensors are commonly used for non-contact water detection, making them ideal for environments that require sensitive and precise measurements, such as industrial automation and environmental monitoring.

Resistive sensors detect water by measuring changes in electrical resistance when water makes contact with two electrodes. Water acts as a conductor, altering the resistance between the electrodes and triggering an alert.

● How they work: These sensors use two electrodes, and when water bridges the gap between them, the electrical resistance decreases. This change in resistance is measured and interpreted as the presence of water.

● Applications: Resistive sensors are widely used in home leak detection systems, plumbing systems, and other areas where simple, low-cost water detection is needed. They are also used in areas like water tanks, where monitoring water levels is important.

Optical sensors use light to detect water. These sensors are based on the principle of light reflection or refraction. When water comes into contact with the sensor, the refractive index of the material changes, and this change is used to detect the presence of water.

● How they work: Optical sensors typically use an infrared light beam, and when water enters the beam’s path, it alters the reflection or refraction of light. The sensor detects this change and alerts the system.

● Applications: These sensors are ideal for sensitive environments such as laboratories, electronics manufacturing, and other applications where non-contact detection is required and precise measurements are critical.

Multiparameter Sensors are advanced sensors that measure multiple water quality parameters, such as pH, turbidity, dissolved oxygen (DO), and oxidation-reduction potential (ORP), all in one device. These sensors are designed for comprehensive water quality monitoring, providing a detailed picture of the water's condition.

● How they work: Multiparameter sensors utilize a combination of sensing technologies, including electrochemical sensors and optical sensors, to measure various water quality parameters simultaneously. This is particularly useful for environments that require constant monitoring of water quality.

● Applications: Multiparameter Sensors are commonly used in large-scale water treatment plants, aquaculture, environmental monitoring, and industrial processes, where monitoring multiple parameters in real-time is essential. By offering a comprehensive solution, they reduce the need for multiple devices, making them both cost-effective and efficient.

Understanding the mechanisms behind water detection sensors can help determine which sensor is most suitable for a specific application.

Conductive water detection sensors are one of the simplest forms of water sensors. They measure the change in electrical conductivity caused by water.

● Mechanism: These sensors use two electrodes separated by a non-conductive material. When water comes into contact with the electrodes, it completes the electrical circuit and reduces resistance, signaling the presence of water.

● Use cases: Conductive sensors are commonly used in plumbing systems, water tanks, and industrial applications, where the presence of water needs to be detected quickly and reliably.

Capacitive water sensors operate on the principle of measuring changes in capacitance.

● Mechanism: When water alters the dielectric properties of the material between two electrodes, the capacitance changes, triggering a response from the sensor.

● Use cases: These sensors are commonly used in sensitive or non-contact water detection applications, such as monitoring for leaks in industrial systems or detecting water in areas where direct contact with water must be avoided.

Optical and ultrasonic sensors both use light and sound waves to detect water.

● Mechanism: Optical sensors detect water by measuring light reflection or refraction changes, while ultrasonic sensors emit high-frequency sound waves and detect changes in the distance to the water surface.

● Use cases: Optical sensors are widely used in industries where water detection needs to be precise and non-contact, such as electronics. Ultrasonic sensors, on the other hand, are ideal for measuring liquid levels or detecting hidden water in inaccessible areas.

Water detection sensors are used across various industries for different purposes. Here are some key applications:

Water sensors are commonly used in homes and businesses to detect leaks and prevent flooding. They can be installed in areas prone to water damage, such as basements, under sinks, and near appliances like washing machines and dishwashers.

● Real-life examples: In a residential setting, water sensors can help detect leaks from pipes or appliances, alerting homeowners to potential flooding and water damage. Commercial buildings often use water sensors to protect equipment and inventory from water damage.

Industries rely on water sensors to monitor equipment, machinery, and systems where water presence could lead to damage. In factories, data centers, and manufacturing plants, water sensors ensure that water-related issues are detected before they cause significant problems.

● Real-life examples: In an industrial setting, water sensors can be used to monitor pipelines, detect leaks in cooling systems, or alert operators about issues with water treatment systems. They help prevent costly repairs and downtime by enabling early detection.

Water sensors also play a critical role in environmental conservation by monitoring the quality and levels of water in natural bodies, such as rivers, lakes, and reservoirs.

● Real-life examples: Environmental agencies use Multiparameter Sensors to track water quality in freshwater ecosystems, measuring parameters like dissolved oxygen and turbidity to assess the health of aquatic environments.

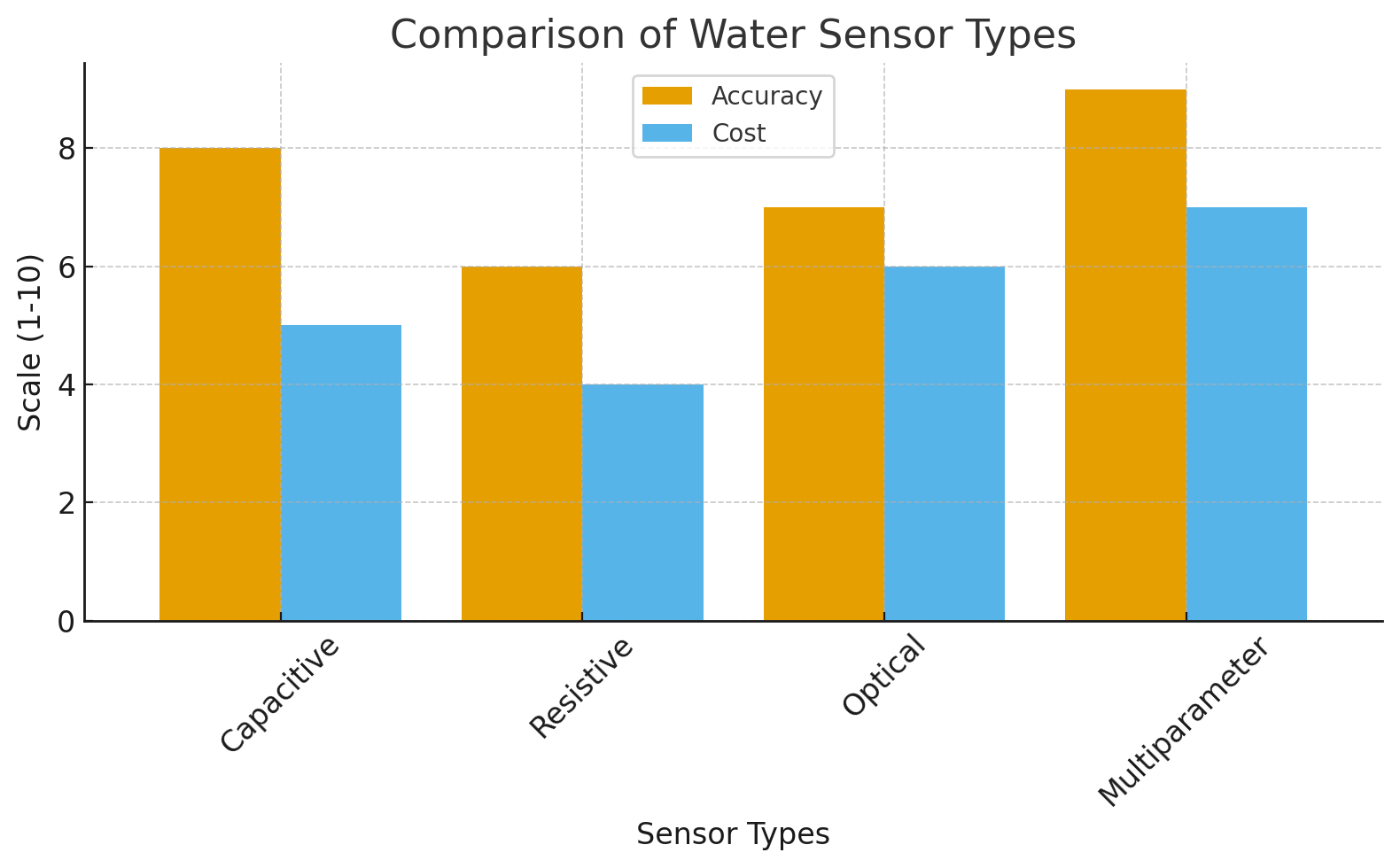

Selecting the right sensor depends on several factors, such as cost, sensitivity, and the specific needs of the application.

Different water sensors come with varying price points, maintenance requirements, and lifespan.

Water sensors need to be accurate and sensitive to ensure timely alerts. When choosing a sensor, it’s important to consider the environmental conditions and the level of detection required.

The future of water detection sensors is promising, with continuous advancements in technology aimed at improving efficiency, accuracy, and integration.

Technologies such as wireless connectivity, artificial intelligence, and machine learning are expected to enhance the functionality of water sensors, allowing for real-time monitoring and predictive capabilities.

● Impact: These advancements will enable more proactive water management, reduce false alarms, and optimize sensor performance.

As technology advances, Multiparameter Sensors are expected to become even more sophisticated, offering real-time data on a wide range of water quality parameters with greater accuracy and lower maintenance requirements.

● Future outlook: In the future, Multiparameter Sensors will likely be integrated into smart water management systems, providing businesses and homeowners with a more comprehensive and efficient way to monitor water.

Choosing the right water sensor depends on the specific needs of your application. Whether monitoring a water tank, pipeline, or environmental water quality, there’s a suitable sensor for every requirement. Multiparameter Sensors are ideal for monitoring multiple water quality parameters at once, offering an efficient and cost-effective solution for large-scale systems. For reliable and accurate water detection, Leadmed Technology provides high-quality sensors that meet the needs of various industries, ensuring optimal water management and protection.

A: A water detection sensor identifies the presence of water in various environments. These sensors can detect leaks, water levels, and quality parameters such as pH and turbidity. Multiparameter Sensors are particularly effective, measuring multiple water quality parameters at once.

A: Multiparameter Sensors measure various water quality parameters like pH, turbidity, and dissolved oxygen simultaneously. They provide comprehensive data for efficient water monitoring in industrial, environmental, and municipal applications.

A: Multiparameter Sensors are cost-effective and efficient, as they measure multiple water quality parameters simultaneously. This reduces the need for multiple sensors, streamlining monitoring in large-scale systems.

A: Common types include capacitive, resistive, optical, and Multiparameter Sensors. Each sensor type is suited for specific applications, from leak detection to water quality monitoring.

A: Multiparameter Sensors offer the advantage of measuring several water quality parameters at once, reducing costs and simplifying monitoring. They are ideal for industrial and environmental applications that require comprehensive water data.